Generators

Driveline Machine Shop has mulitple marine generator brands to offer Newfoundland and Labrador.

From 5kW to 1056kW

Yanmar Marine Generators by Driveline

12kW – 24.9kW keel cooled marine generator.

- Deep Sea Controllers

- Keel cooled

- Stamford Alternator

- In Stock

Cummins ONAN Marine Generators

No matter your power requirements, Cummins has you covered with our complete generator range from 4kW to 110kW.

EPA 3 / Stage V, Powered by Cummins engines

Optimized mounting system greatly reduces vibration

Electronic frequency control – a must for digital appliances and computers requiring quality power

More than 100 years of marine experience stand behind every Cummins Onan Marine generator set

Kohler Marine Generators

Kohler Generators are now available at Driveline, from 6kW – 500kW

For more information please see marine product guide

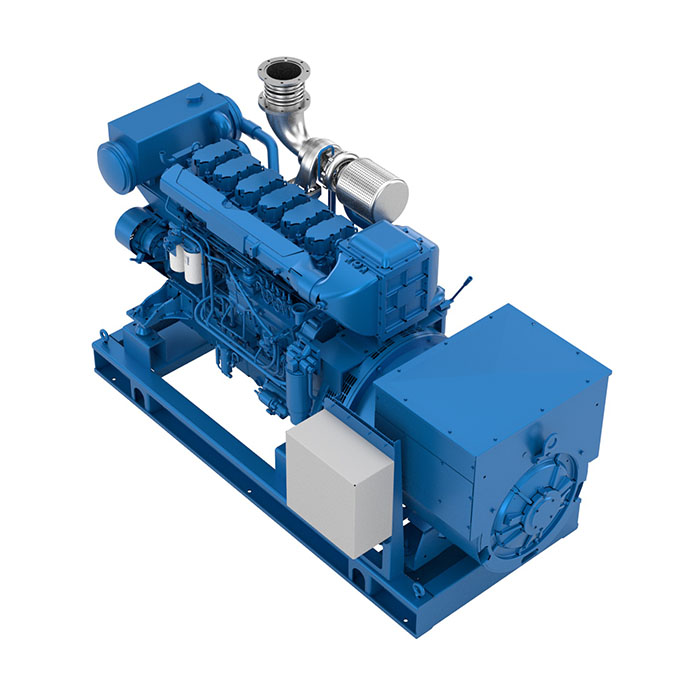

baudouin Marine Generators

Baudouin offers a wide range of marine generator from 84kWe – 1056kWe sets designed for use under the most extreme marine conditions. Baudouin’s wide range of marine products offers you a one-stop shop for marine power and control solutions.

IMO 2 and IMO 3 & Comes 50hz or 60hz

For More information please see the Marine Product Guide